The

dried fruit production line is specially designed for industrialized food processing and mass production. It has a wide range of applications, green and environmentally friendly, low energy consumption, and is simple to operate and convenient. GELGOOG can offer customized dried fruit processing solutions.

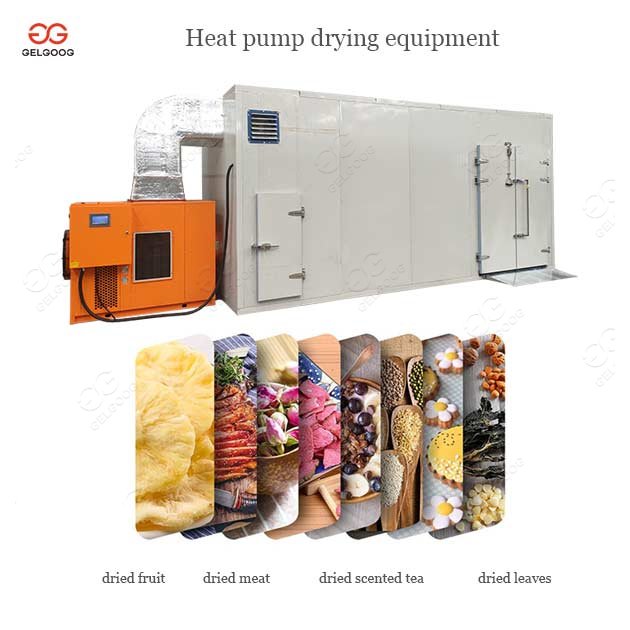

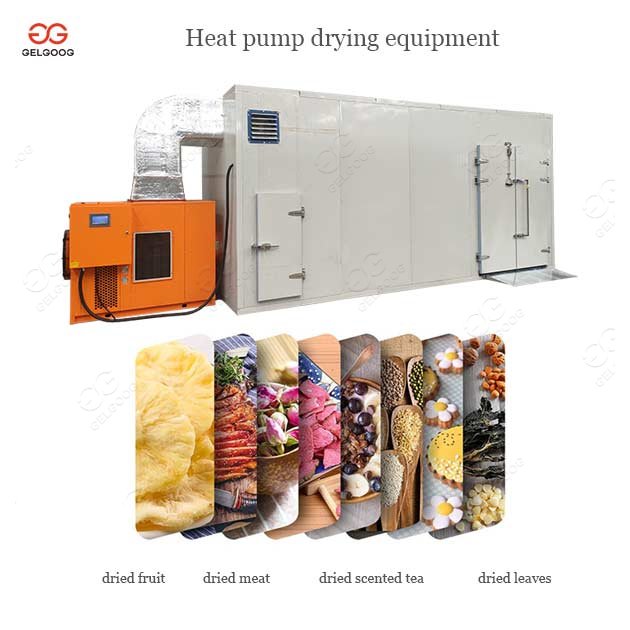

Introduction of heat pump drying equipment

Introduction of heat pump drying equipment:

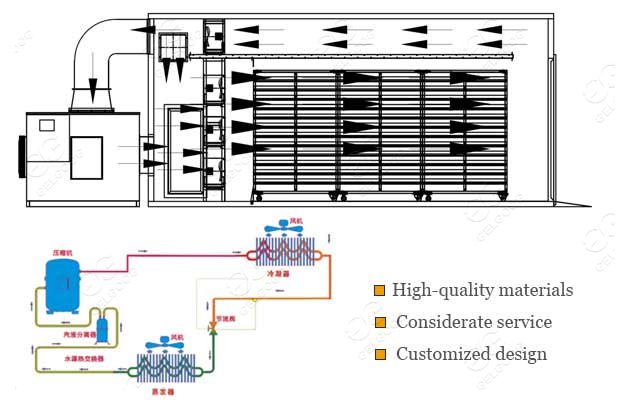

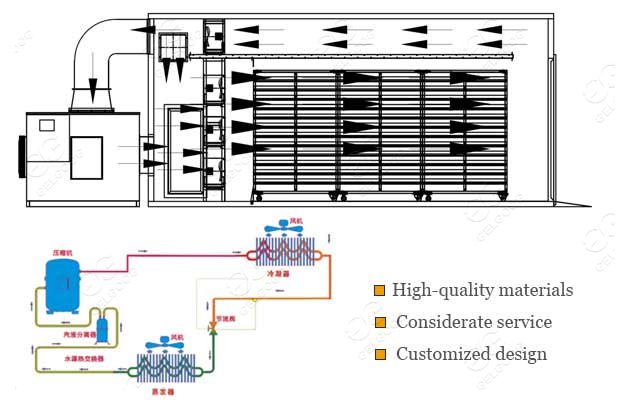

※ The heat pump dryer euipment uses the principle of reverse Carnot cycle to absorb heat from the air and transfer it to the room, thereby increasing the temperature in the drying room, and cooperating with fans and other equipment to achieve drying of materials.

※ The heat pump is mainly composed of condenser-compressor-throttle valve-condenser-compressor and other devices to form a circulating system. The refrigerant circulates in the system under the action of the compressor.

Working Principle of dried fruit production line

The heat pump condenser transfers heat to the air in the heat pump drying room, and the hot air heats the dried materials under the action of the circulating fan, and at the same time takes away the moisture of the materials.

1. The heating process of the heat pump drying room system: during the drying process of the material, the heat pump host cyclically heats the drying room. When the temperature in the drying room reaches the setting (for example, the temperature is set to 60°C), the heat pump host stops heating, and when the temperature in the drying room is lower than the set value, the heat pump host starts to supply heat.

2. The process of dehumidification: Dehumidification system, with automatic system control. For example: set temperature: 55℃; humidity: 60%; when the temperature and humidity in the drying room reach the set value, the exhaust fan will automatically start to discharge the humid air in the drying room into the environment; When the temperature and humidity of the dry room are lower than the set value, the dehumidification system will automatically shut down.

The dehydrated fruit processing line can be used to process

mango, lemon, banana, ginger, garlic, fig, chili, onion, moringa leaves, tomato, pineapple, coconut flakes, mint herbs, seaweed etc.

The dried fruit production line adopts a PLC automatic control system to control the temperature and humidity in the drying room, and can set the temperature, humidity and drying time of the drying, so as to adapt to different drying materials. There is a temperature and humidity sensor in the drying room to monitor the temperature and humidity changes in the drying room in real time. The finished dehydratored products after drying should be sorted, packaged and stored in time to avoid moisture regain affecting the quality and storage time of the final products.

Brand:GELGOOG

Brand:GELGOOG Capacity:Can be customized

Capacity:Can be customized WhatsApp: 008618537181190

WhatsApp: 008618537181190

E-Mailggjx@gelgoog.com

E-Mailggjx@gelgoog.com Contact0086-18537181190

Contact0086-18537181190 Whatsapp0086-18537181190

Whatsapp0086-18537181190 TOP

TOP