As the demand for high-quality fried shallots and other thin-sliced vegetable products grows globally, food processors are increasingly seeking continuous frying solutions to improve efficiency, consistency, and product safety. Traditional batch frying often limits production capacity, increases labor costs, and creates challenges in maintaining consistent quality.

For manufacturers looking to scale up, continuous shallots frying systems provide an ideal solution, allowing for high-volume production with automated oil management and filtration, precise temperature control, and consistent product output.

Challenges in Fried Shallots Production:

Many processors of shallots and similar thin-sliced vegetables face common pain points:

Inconistent quality: Batch frying can result in uneven color, texture, and taste.

High labor dependency: Manual handling of large quantities increases operational costs and risk of human error.

Oil degradation and waste: Frequent oil replacement or poor filtration can affect product flavor and shelf life.

Scaling limitations: Expanding production with batch processes often requires multiple machines, increasing floor space and maintenance needs.

The Continuous Frying Solution For fried shallots:

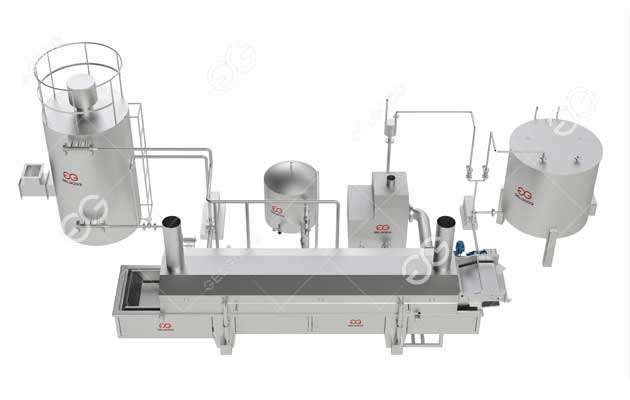

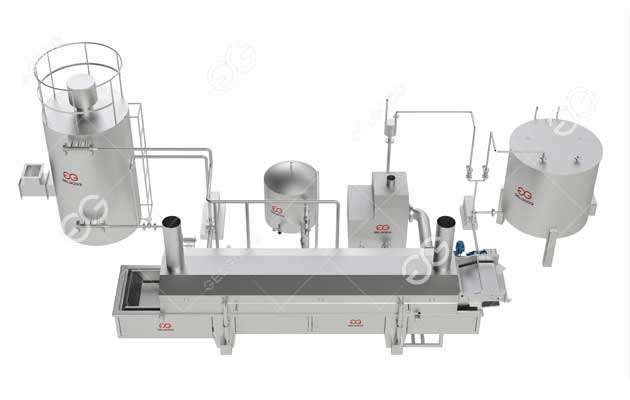

A modern continuous frying line is designed to address these challenges and optimize every stage of production:

Automated Feeding System – Uniformly feeds thin-sliced shallots into the fryer to ensure consistent cooking.

Precision Temperature Control – Maintains ideal frying temperature for golden, crispy shallots without overcooking.

Oil Management & Filtration – Continuous oil circulation and filtration reduce waste, preserve flavor, and extend oil life.

High-Volume Output – Capable of handling large quantities efficiently, suitable for scaling production.

Integrated Cooling & Discharge – Ensures that fried shallots are cooled quickly and conveyed smoothly for packaging.

These features not only improve product consistency and quality, but also reduce operational costs and downtime, making it easier for food processors to meet market demand.

Why Choose a Continuous Frying Line for Shallots:

Consistency: Each batch achieves uniform color, crispiness, and flavor.

Efficiency: Automated systems significantly reduce labor requirements.

Flexibility: Can be adapted to other thin-sliced vegetables or high-sediment ingredients.

Sustainability: Advanced oil filtration and management reduce oil consumption and waste.

Scalability: Easily integrates with downstream packaging and seasoning systems to support growing production needs.

Manufacturers considering upgrading to a continuous frying line benefit from professional guidance in layout design, equipment selection, and process optimization. Choosing the right fryer model, matched to your production volume and product characteristics, ensures that your fried shallots achieve superior quality while maximizing operational efficiency.

For food processors seeking to transform their shallot frying operations, a continuous frying system is a strategic investment. By providing high-volume, consistent, and safe frying, this solution addresses key pain points such as labor cost, oil management, and product quality, allowing manufacturers to confidently scale their operations and meet growing consumer demand.

Leave meaage for more information and quotation.

Fruit Vegetable Processing

Fruit Vegetable Processing Nuts Processing Solution

Nuts Processing Solution Pastry Processing Solution

Pastry Processing Solution