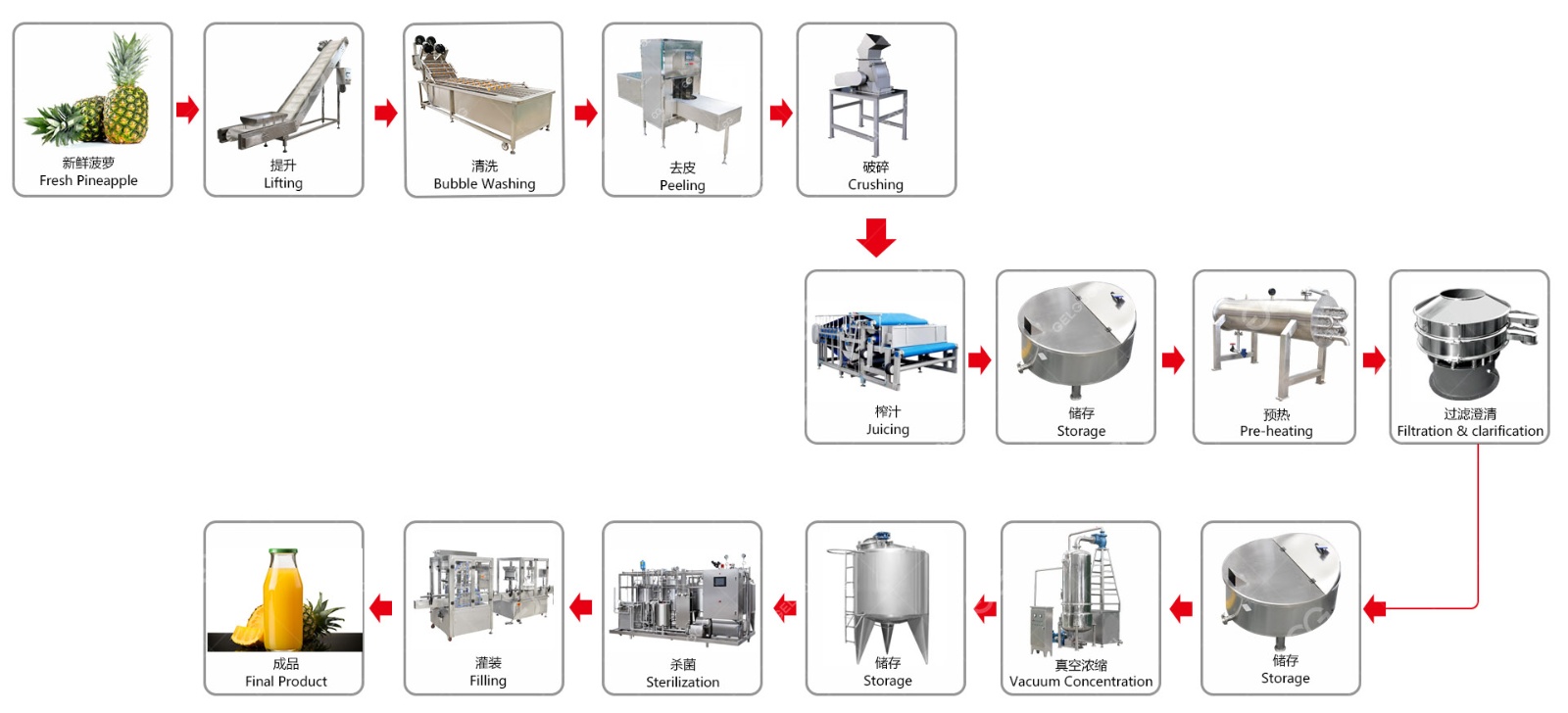

Small Scale Pineapple Juice Production Line Exported to Burundi | Affordable Solution for Tropical Juice Processing

Recently, a compact pineapple juice production line manufactured by our company was successfully shipped to Burundi, East Africa. Designed for small to medium-sized juice processing businesses, this turnkey solution helps local enterprises transform fresh tropical fruits into market-ready bottled juice.

Jun 26, 2025

Fruit Vegetable Processing

Fruit Vegetable Processing Nuts Processing Solution

Nuts Processing Solution Pastry Processing Solution

Pastry Processing Solution