The fresh-cut vegetable processing line, also known as salad production line, is an automated solution designed for cleaning, cutting, sterilizing, drying, and packaging fresh vegetables. This line is widely used in central kitchens, food processing plants, vegetable supply chains, and ready-meal manufacturers.

Clean Vegetable Processing Flow

Vegetable Sorting & Conveying: Manual or automatic sorting to remove damaged leaves, impurities by sorting table.

Vegetable Washing System: Multi-stage cleaning using air bubble, ozone, and high-pressure water

Vegetable Cutting: Precise cutting of vegetables into desired shapes (strips, slices, cubes)

Sterilization Blanching (Optional): Kills bacteria and prolongs shelf life by blanching machine

De-watering Air Drying: Removes surface moisture to prevent spoilage and ensure quality packaging

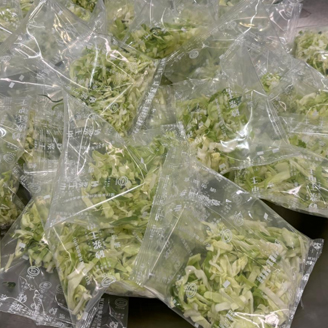

Weighing Packaging: Suitable for pillow packaging, tray sealing, vacuum packing

Fruit Vegetable Processing

Fruit Vegetable Processing Nuts Processing Solution

Nuts Processing Solution Pastry Processing Solution

Pastry Processing Solution