Gelgoog full automatic tomato paste production line is designed for high-efficiency processing, with a capacity of 500-3000kg per hour, ideal for medium and large-scale tomato paste production. This advanced line integrates washing, sorting, crushing, preheating, pulping, vacuum concentration, sterilization, and aseptic filling, ensuring a continuous and hygienic production process.

Whether you're producing thick tomato paste in drums for industrial use or ready-to-eat tomato sauce in sachets or bottles, this production line can be customized according to local market preferences, packaging needs, and processing capacity.

FUNCTION

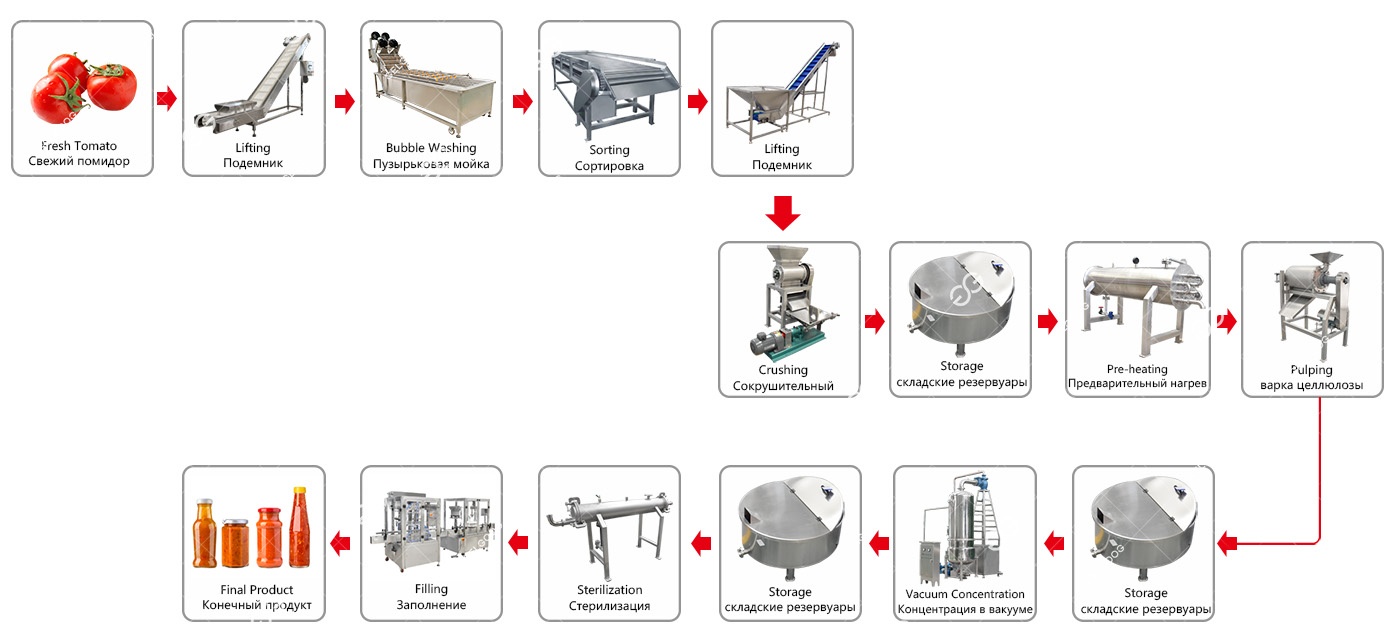

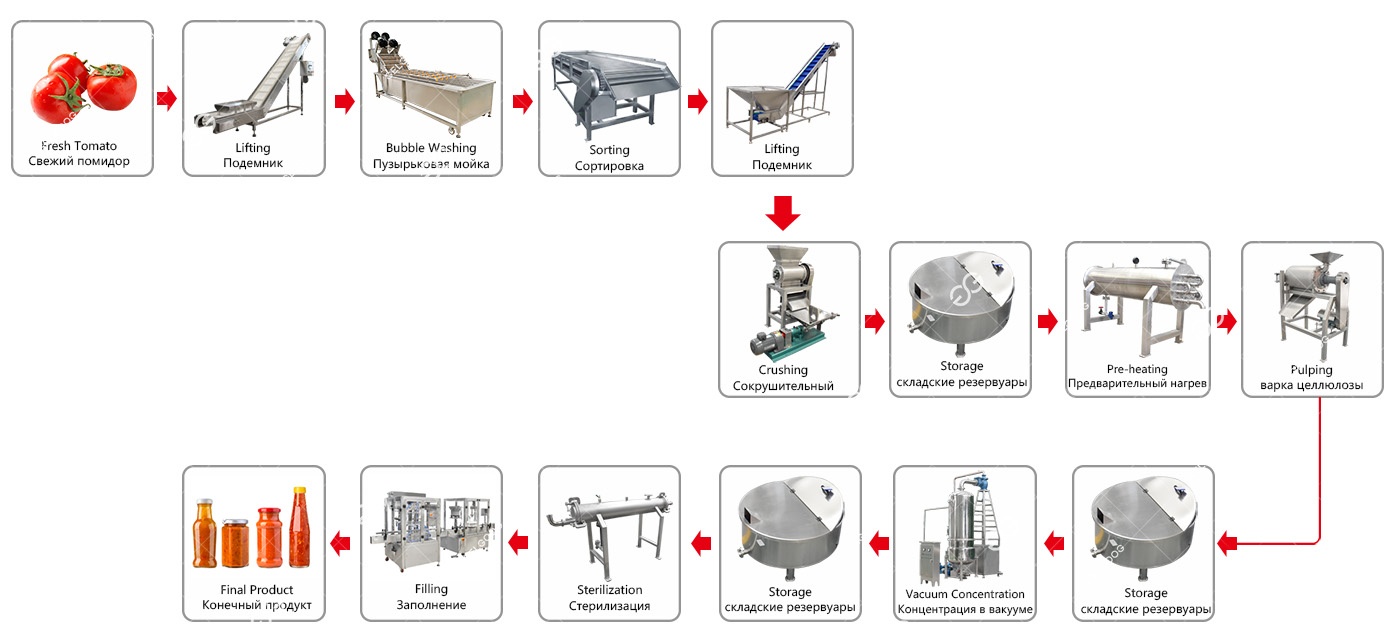

This production line performs a series of processing steps to convert fresh, ripe tomatoes into finished products like tomato paste and tomato sauce. The main processes include:

Washing & Sorting – Ensures removal of mud, sand, leaves, and other impurities.

Crushing & Pulping – Breaks down tomatoes and separates seeds and skins.

Concentration – Reduces the water content to obtain concentrated tomato paste.

Blending & Seasoning (for sauce) – Adds ingredients like salt, sugar, vinegar, and spices for tomato sauce production.

Sterilization – Ensures microbial safety and extends shelf life.

Aseptic Filling & Packaging – Fills finished product into drums, sachets, bottles, or pouches under sterile conditions.

Features

✅ High Automation: Fully automatic operation reduces manual labor and improves hygiene.

✅ Multi-product Capability: Suitable for producing tomato paste, ketchup, tomato sauce, and other derived products.

✅ Customizable Output: Processing capacity from 500kg/h to 20 tons/h depending on demand.

✅ Energy Efficient: Designed to reduce steam and electricity consumption.

✅ Stainless Steel Build: Meets international food safety standards.

✅ Easy Maintenance: Modular design with accessible components for cleaning and servicing.

Ideal Applications

This tomato processing line is ideal for:

✅ Food manufacturers in Africa looking to value-add to fresh tomatoes and reduce post-harvest waste.

✅ Agricultural cooperatives and tomato farming hubs seeking to integrate downstream processing.

✅ Export-oriented factories producing bulk tomato paste for international markets.

✅ Local sauce brands that produce flavored tomato sauces in small and medium batches.

Additional Information

Packaging Options: Aseptic bags in drums, sachets, glass bottles, PET bottles, tin cans, and pouches.

Tomato Paste Brix: 28–30%, 36–38%, or customizable.

Tomato Sauce Specification: Viscosity and seasoning adjusted to local taste.

Installation & Training: On-site installation and operator training available in African countries.

After-sales Support: 24/7 remote technical support and spare parts supply.

Regional Experience: GELGOOG has successfully installed Ghana, Ethiopia Uruguay, Uzbekistan, Burkina Faso, Algeria ect ..

Fruit Vegetable Processing

Fruit Vegetable Processing Nuts Processing Solution

Nuts Processing Solution Pastry Processing Solution

Pastry Processing Solution