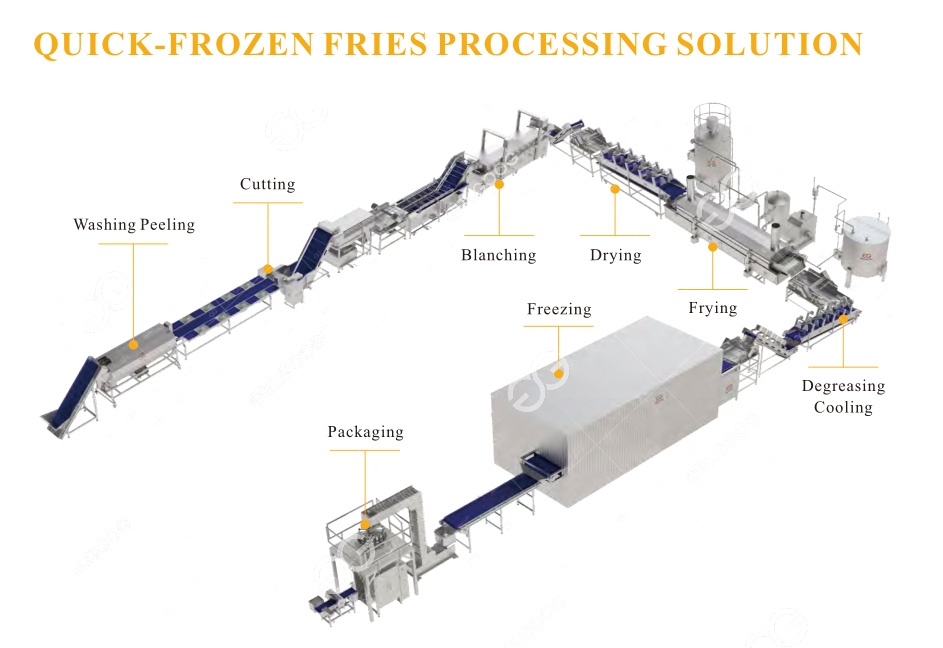

Frozen French fries are one of the world’s most popular convenience foods, and demand continues to grow across supermarkets, fast-food chains, and food service suppliers. But many buyers and new investors still ask the same question: how are french fries made in a factory, and what equipment is needed to ensure consistent quality at scale?

Today’s industrial French fries are not simply “cut potatoes and frying.” In a professional facility, every stage is engineered to control moisture, texture, oil absorption, and food safety—because small mistakes in processing can lead to unstable crispness, dark color, high oil content, or short shelf life.

This article walks through the key steps in modern factory production, and explains why a fully integrated french fries production line is critical for brands aiming to compete in the frozen fries market.

From Raw Potatoes to Uniform Fries: The Process Starts with Cleaning

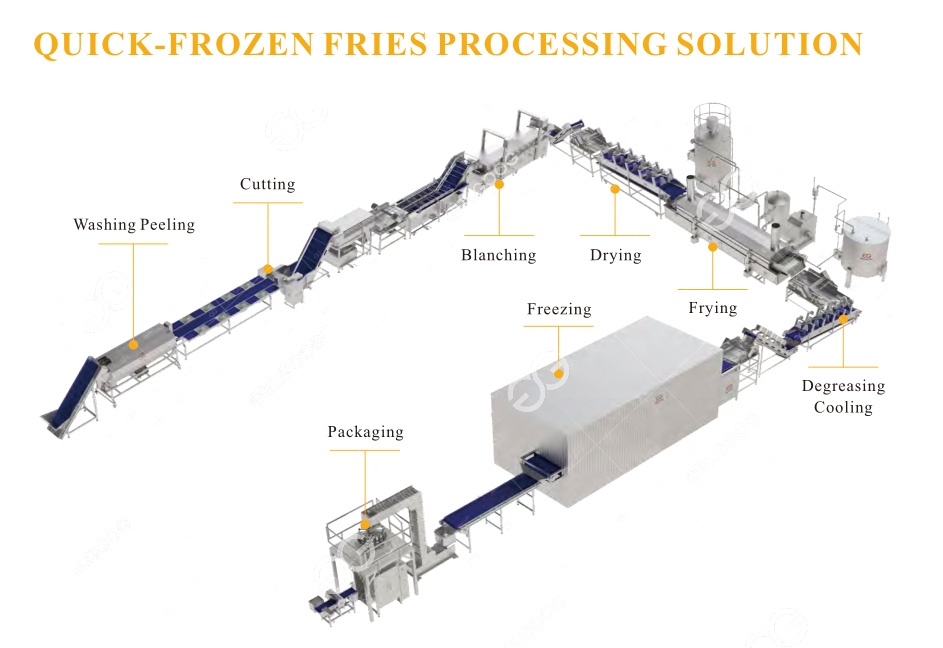

In factory production, the first priority is to remove soil, sand, and impurities while protecting the potato surface. Potatoes are typically washed using high-pressure water jets, which dislodge dirt before peeling begins. In the french fry industry, there are two main peeling methods: abrasive peeling and steam peeling.

Abrasive peeling (also known as carborundum peeling) removes potato skins by rubbing the surface against abrasive rollers or lining. This method is widely used because it is simple, stable, and cost-effective—especially for small and medium processing lines. However, abrasive peeling often causes slightly higher flesh loss, and the surface finish may be less clean for premium frozen fries.

Steam peeling, by contrast, uses high-pressure steam to loosen the potato skin. After steaming, the potatoes pass through scrubbers or water sprays to remove the loosened peel. Steam peeling is common in large-scale french fry factories because it delivers a cleaner appearance, improves yield, and provides more consistent peeling results. The tradeoff is higher equipment investment and the need for a reliable steam system.

When selecting the right peeling method, processors usually consider the potato variety, production capacity, desired product grade, and overall operating cost. For high-end frozen fries where yield and appearance matter most, steam peeling is often the preferred option. For smaller factories or budget-limited projects, abrasive peeling remains a reliable and practical choice.

High-Speed Cutting: Why Factory Fries Look So Consistent

After peeling, potatoes move into high-speed cutting systems designed to create uniform fry strips. Many industrial cutters use water-driven transport and high-speed slicing, where potatoes can move through pipes at extremely high velocity—often compared to speeds of 60–70 mph.

The purpose of this technology is simple: uniform thickness. Consistent fry dimensions ensure consistent blanching, frying, freezing, and final crispness. If thickness varies, the factory will see uneven color, broken fries, and inconsistent texture after cooking.

Sorting and Blanching: Where Quality Control Really Begins

Once the fries are cut, modern plants rely on sorting systems—often including laser scanners—to remove defective strips, dark spots, and irregular pieces. This is one of the most important stages for premium-grade frozen fries.

Next comes blanching. The fries are blanched in hot water to remove excess surface starch and stabilize the internal structure. This step helps reduce oil absorption later, improves final texture, and ensures the fries cook evenly.

For manufacturers selling to food service buyers, blanching is often the difference between “average fries” and fries that deliver a stable eating experience in every batch.

Drying Before Frying: A Key Step for Lower Oil and Better Crispness

After blanching, fries must be dried using air systems to remove surface moisture. Skipping or underperforming in this stage often leads to higher oil absorption, unstable crust formation, and inconsistent appearance.

Drying also helps protect the fryer from excessive water entering the oil, which can accelerate oil degradation and increase operating costs.

Pre-Frying and De-Oiling: Building the Crust Without Overcooking

In most frozen fries factories, fries are pre-fried for about 2 minutes in hot oil. The goal is not to fully cook the fries, but to create a light crust and lock in structure.

Immediately after frying, fries go through a de-oiling section, often using a vibrating conveyor. This removes excess oil from the surface, helping the final product remain lighter, cleaner, and more stable during storage.

This stage is where professional factories win or lose in terms of cost control, oil management, and product quality.

Freezing and Packaging: Locking in Freshness for Global Supply

After pre-frying, fries are frozen using IQF (Individually Quick Frozen) technology. In modern factories, this is done in a tunnel freezer where fries are rapidly frozen to protect structure, prevent clumping, and maintain quality during transportation.

Once frozen, fries are packed using automated weighing and packaging systems. For brands selling multiple formats, packaging lines must handle different bag sizes efficiently, from retail packs to food service bulk bags.

Quality Control: Automated + Human Inspection for Safety and Consistency

Frozen French fries production is highly standardized, and quality control is built into the line. Automated systems monitor defects, size, and color, while operators verify hygiene, oil quality, and processing parameters.

This combination is essential for meeting export standards, retailer requirements, and long-term brand stability.

Why Many Fries Projects Fail: The Real Issue Is Line Integration

Many new fries producers underestimate how connected each step is. In reality, fries quality depends on the balance between washing, cutting, blanching, drying, frying, de-oiling, freezing, and packaging.

If the factory uses mismatched equipment, the line will suffer from unstable throughput, excessive waste, inconsistent color, high oil consumption, and frequent downtime. That is why professional manufacturers prefer working with suppliers who can provide an integrated line—not just single machines.

Looking for a Complete French Fries Production Line?

If you are planning a frozen fries factory or upgrading an existing facility, choosing the right processing solution is critical. A well-designed line improves yield, reduces oil and energy costs, and helps you deliver stable product quality for retail or food service markets.

Leave a message on this page to request a technical proposal, including recommended capacity, line layout, equipment specifications, and quotation based on your target product and production plan. Email to info@gelgoog.com

Fruit Vegetable Processing

Fruit Vegetable Processing Nuts Processing Solution

Nuts Processing Solution Pastry Processing Solution

Pastry Processing Solution