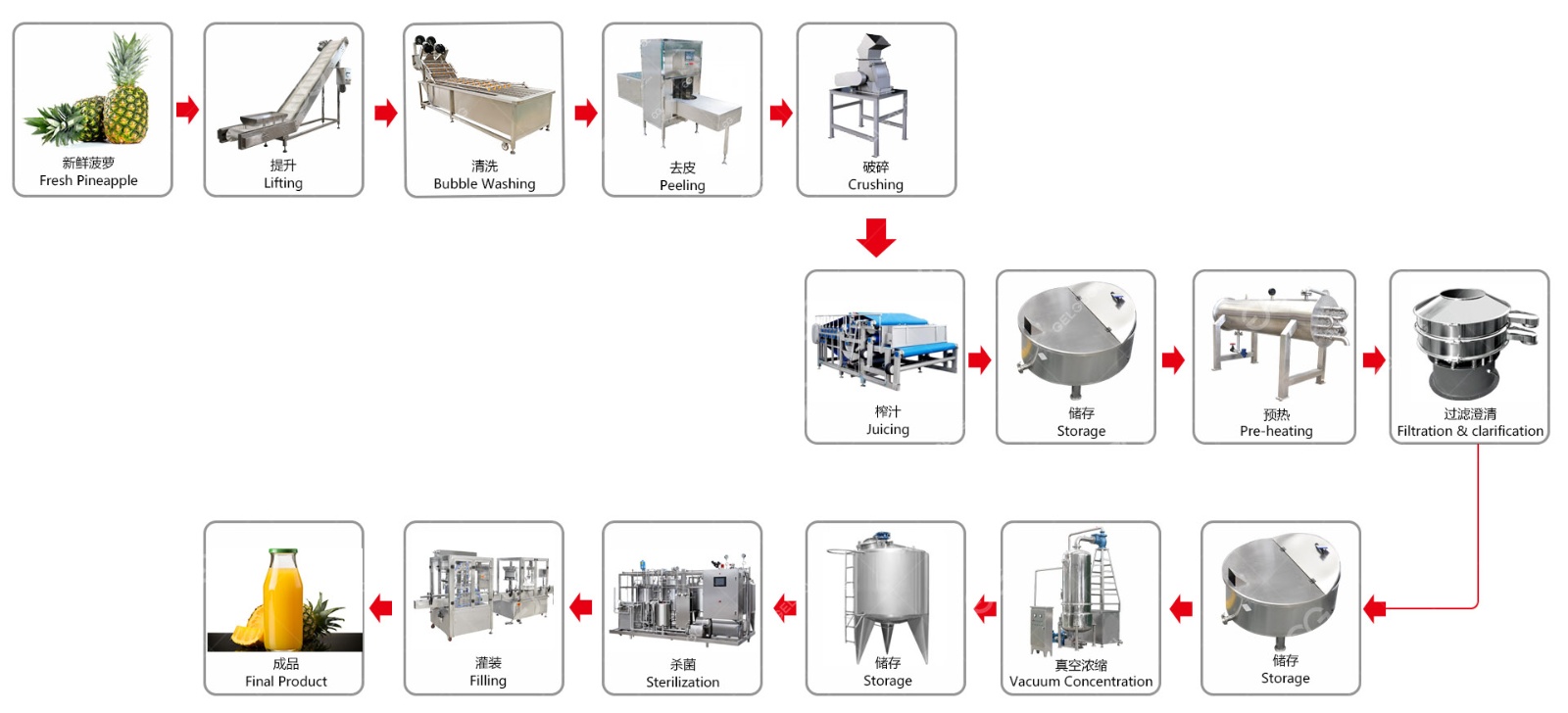

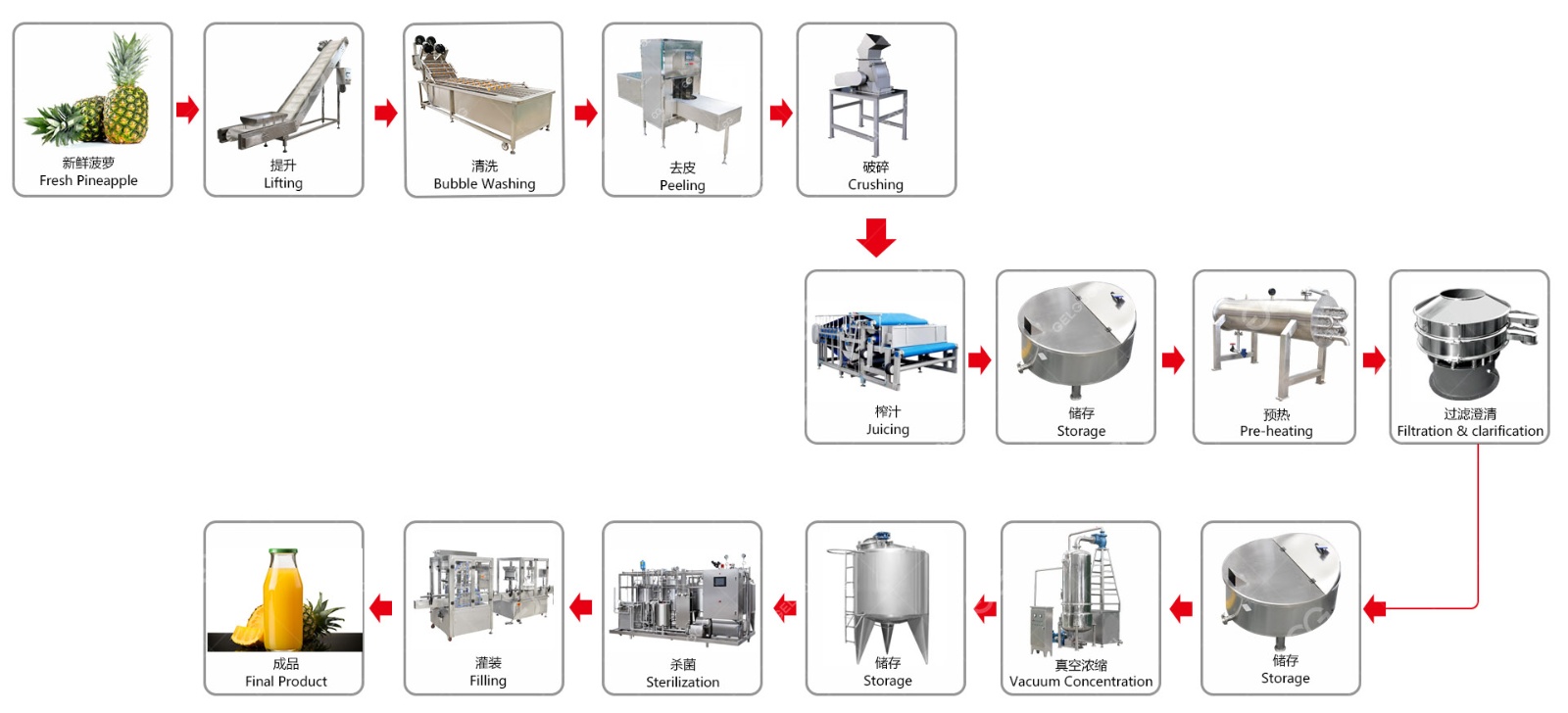

What are the steps in the pineapple processing process? 6 key steps here show you the standard flow for pineapple juice production:

Sorting & Cleaning: Fresh pineapples are sorted to remove damaged ones, then washed with high-pressure water to eliminate dirt and pesticides.

Peeling & Coring: Automated machines peel the outer skin and remove cores, ensuring only flesh is processed.

Crushing & Pressing: Pineapple flesh is crushed into pulp, then pressed to extract juice (with optional enzyme treatment to boost yield).

Filtration: The juice is filtered through fine sieves to remove pulp residues, achieving a clear texture.

Pasteurization: Heat-treated at 85-90°C for 15-30 seconds to kill bacteria, extending shelf life.

Cooling & Packaging: Rapidly cooled to specified storage temperature, then filled into sterile bottles/cartons (aseptic packaging for longer freshness).

Gelgoog’s pineapple processing line handle all steps efficiently, with food-grade equipment and customizable capacity (500-5000L/h). Contact us for tailored solutions!

Fruit Vegetable Processing

Fruit Vegetable Processing Nuts Processing Solution

Nuts Processing Solution Pastry Processing Solution

Pastry Processing Solution